-

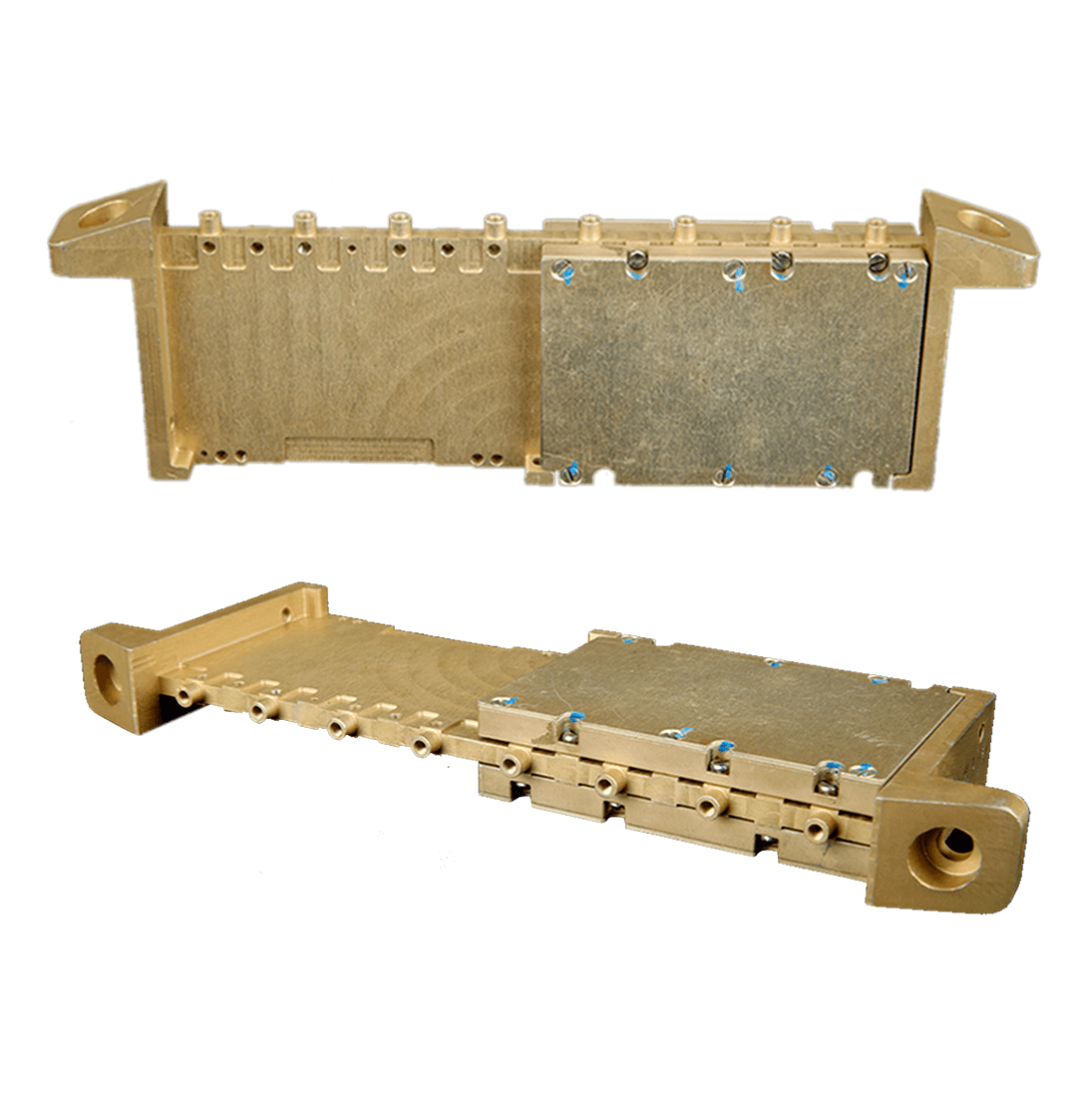

Thin-walled Phase-change Cold Plate of TR Module

Product advantages

Product advantagesStructure-function integration

Innovative processing, filling and sealing technology

Phase-change material with high enthalpy

Light weight and large heat storage

-

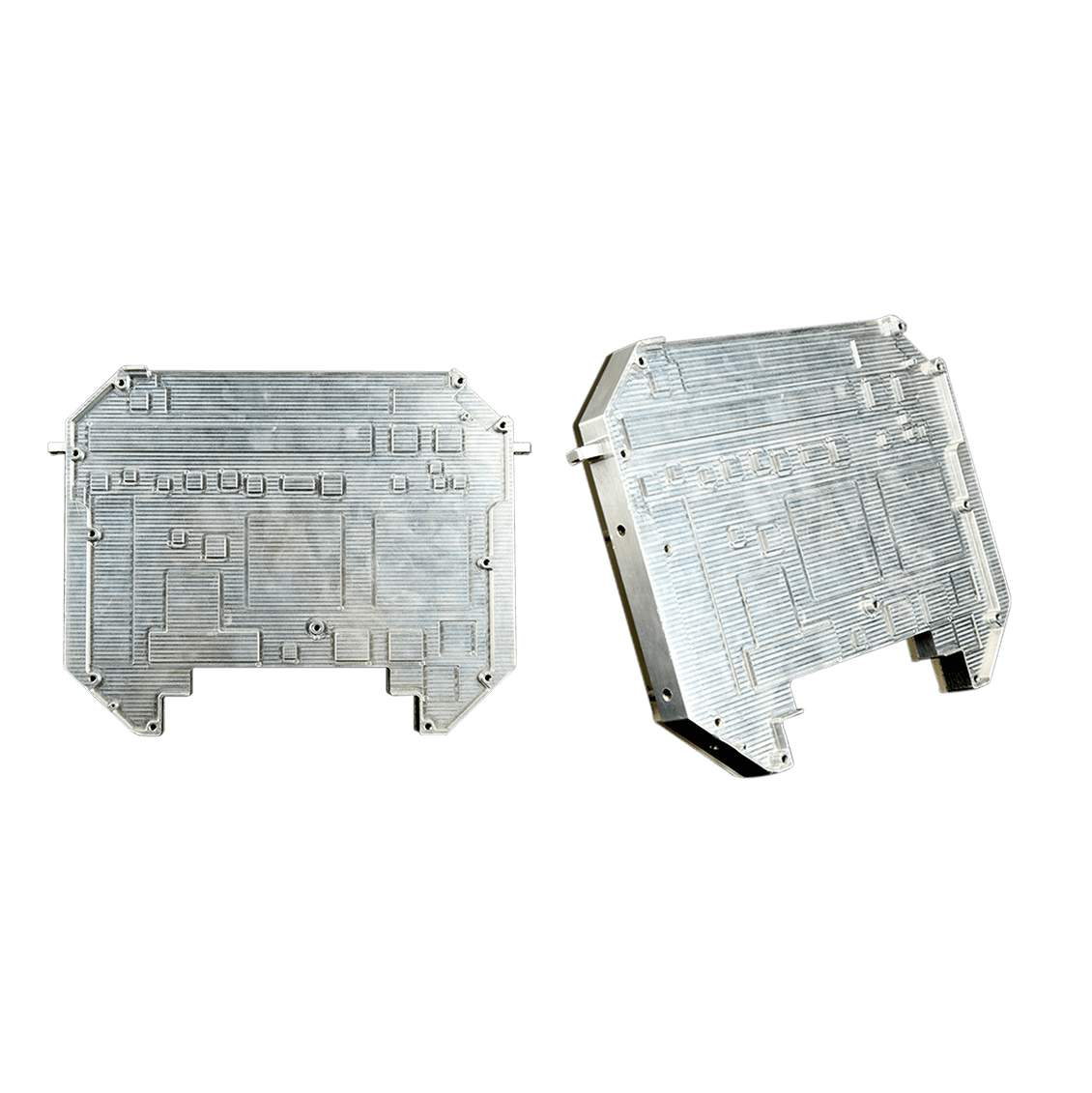

Phase-change Cold plate for Signal Processing

Product advantages

Product advantagesSimple structure

Phase-change material with high enthalpy

Innovative low pressure sealing technology

Simple processing technology

Large heat storage

Non-deformation

-

Composite Phase-change Cold Plate for Temperature Equilibrium

Product advantages

Product advantagesIntegration of high thermal conductivity and temperature equilibrium components and phase-change

Integrated machining

Phase-change material with high enthalpy

Long temperature control time

High equivalent thermal conductivity

Automatic filling and low pressure sealing technology

Large heat storage

-

Composite Phase-change Cold Plate for Liquid Cooling

Product advantages

Product advantagesLiquid cooling for ground commissioning

Heat storage for practical work

Integrated forming, welding and sealing technology

Long-term uninterrupted testing

Meet corresponding thermal design requirements

Space saving and reliable performance

-

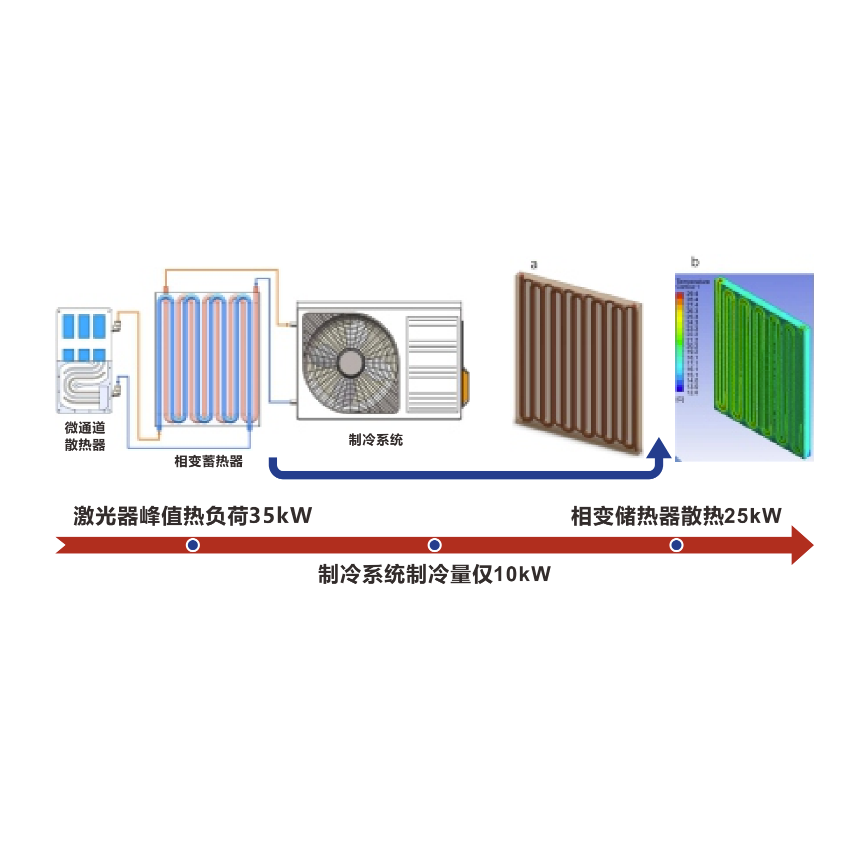

Active-passive Composite Thermal Control Components and Systems

Product advantages

Product advantagesActive-passive composite

Low total cooling power consumption

Enhanced heat transfer

Small size and light weight

Small supporting refrigerating units

Maximize utilization of phase-change materials

-

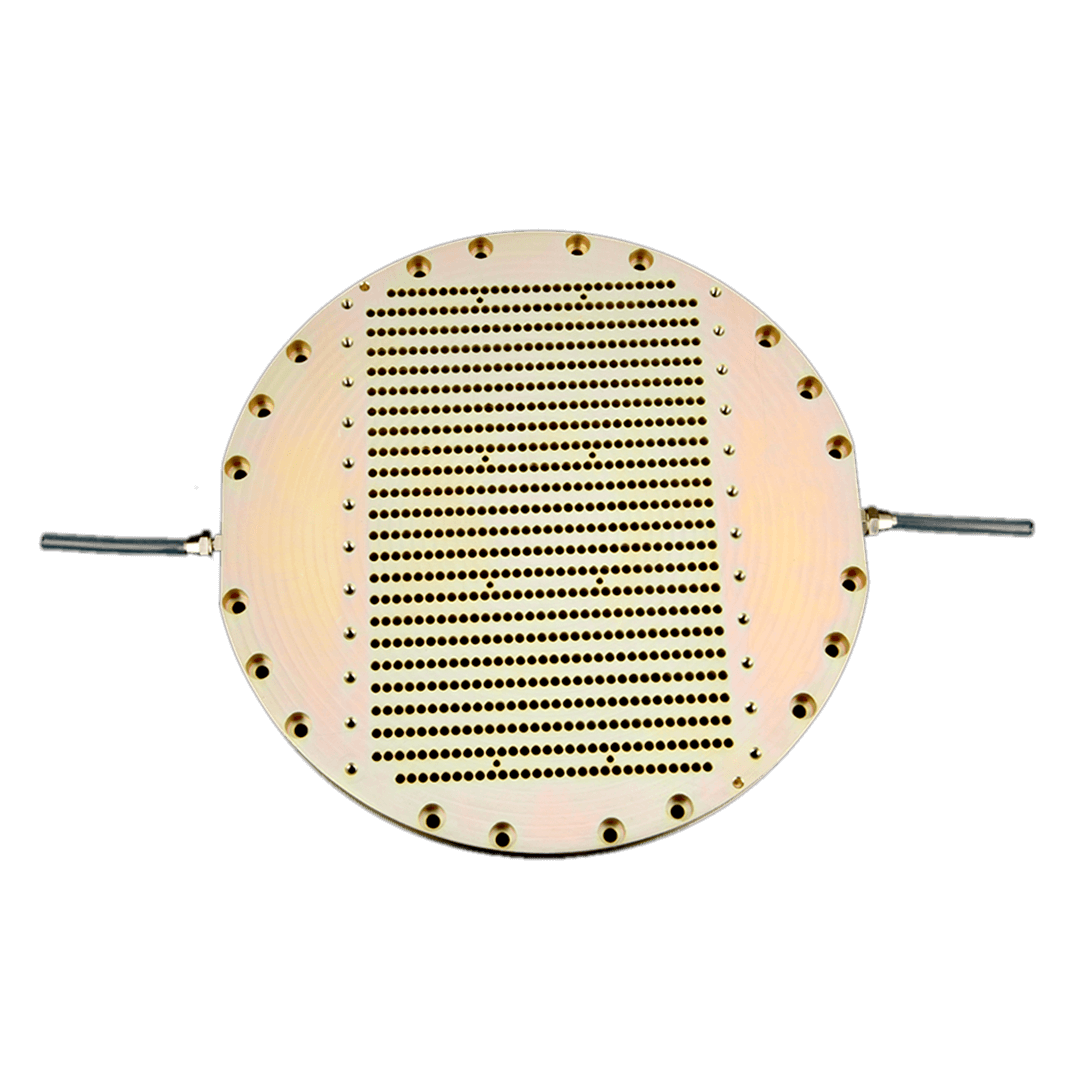

Laminated Micro-channel Antenna Cold Plate for Liquid Cooling

Product advantages

Product advantagesVariable cross-section flow channel

Large heat transfer are

Integrated processing and forming

Improve heat transfer efficiency

Low thermal resistance and high heat transfer coefficient

High reliability and low cost

-

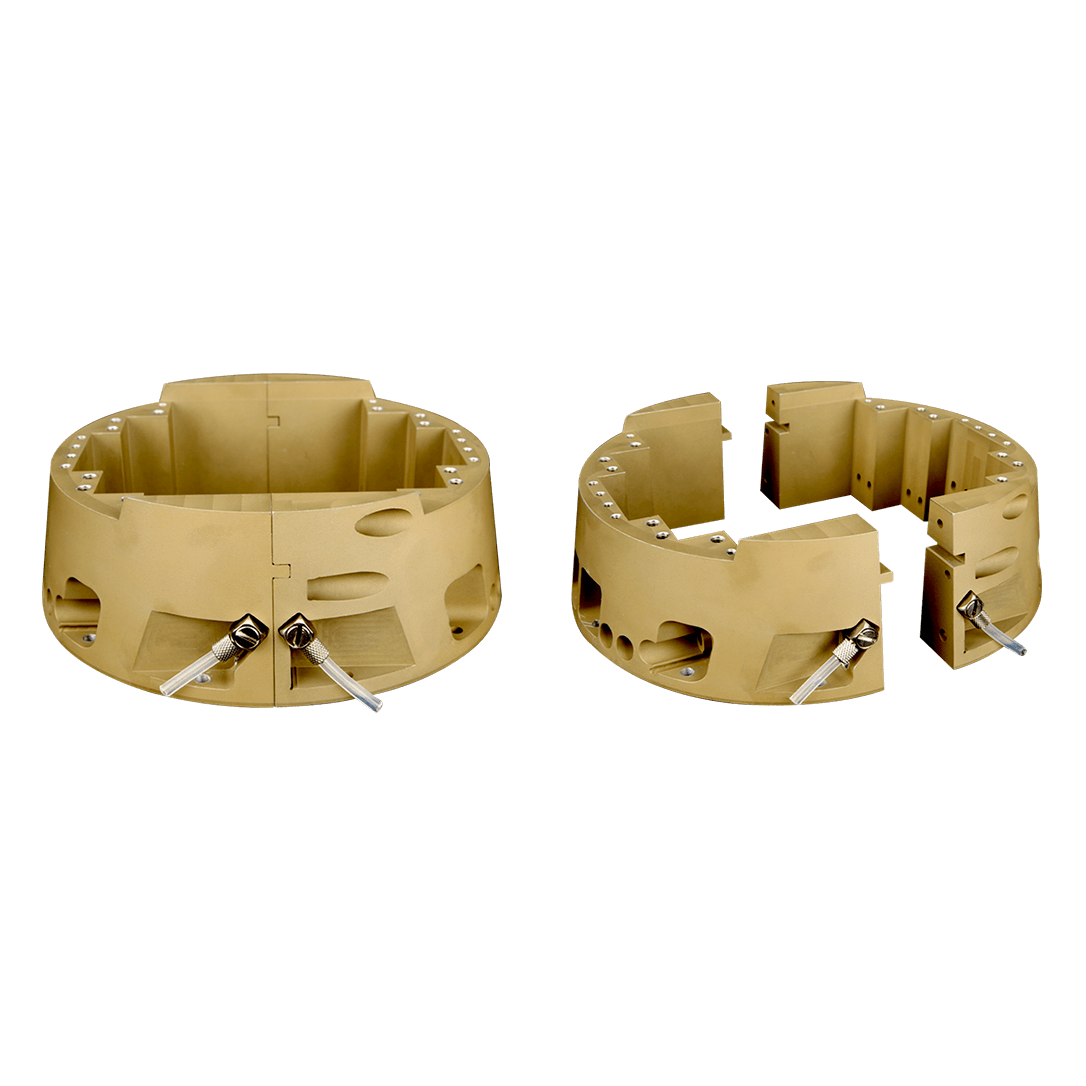

Conical Irregular-shaped Multi-layer Components for Liquid Cooling

Product advantages

Product advantagesVariable cross-section flow channel

Large heat transfer area

Integrated processing and forming

Improve heat transfer efficiency

Low thermal resistance and high heat transfer coefficient

High reliability and low cost

-

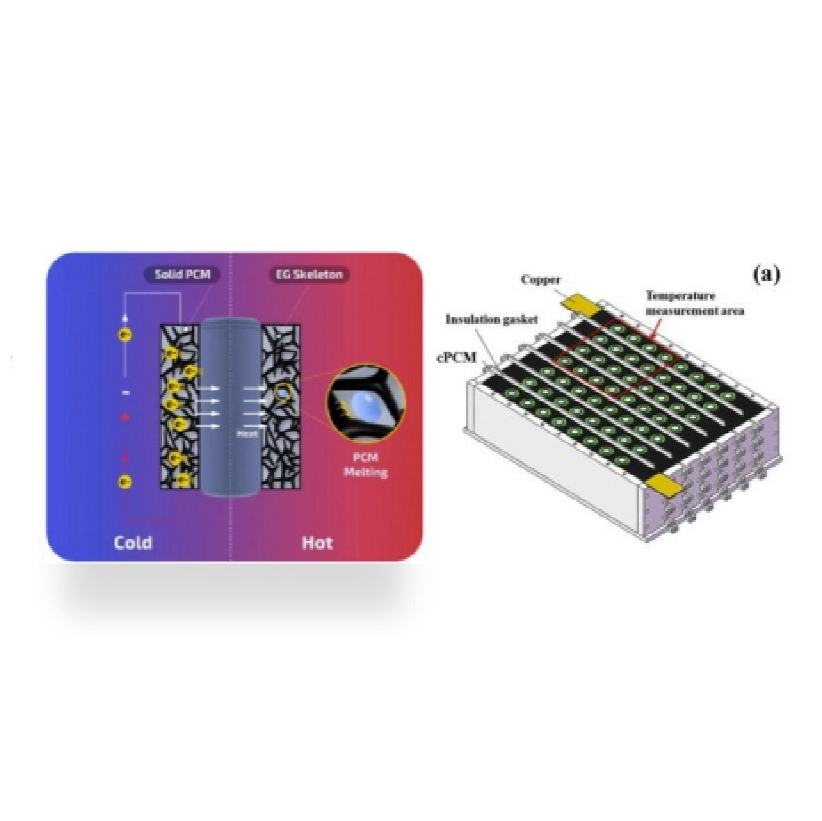

Integrated Thermal Control of Phase-change Materials

Product advantages

Product advantagesThe temperature rises over 10℃/min

The maximum temperature of the battery is less than 55°C

The temperature difference in the heating process is less than 4° C

-

-

Hotline

- 0086-027-87981568

-

-

-

Email

- sales@yoec.com.cn

-

-

-

Contact

Us

-

-

-