-

Quadrupole Winding Machine

Product advantages

Product advantagesThe equipment structure design perfectly matches the quadrupole symmetrical winding process, and the winding process is simple and convenient to operate

The equipment runs stably and has a simple and beautiful appearance

Adopt precision servo motion control system and PLC control system, with accurate operation and high degree of automation

The image acquisition and display system is adopted, which is intuitive and simple to operate

The online tension closed-loop feedback system is adopted, and the tension in the winding process is stable and the yield is high

The winding process automatically records all kinds of data, including tension, speed, length, turns, layers, etc.

-

Fiber Coil Winding Machine

Product advantages

Product advantagesSuitable for winding high-precision optic fiber coils with various quadrupole, octupole and hexadecapole symmetrical winding methods

Adopt precision marble platform base to ensure the stable operation of equipment

Adopt precision servo motion control system and PLC control system, with accurate operation and high degree of automation

Using image acquisition and display system, the touch screen control operation is more concise

The online tension closed-loop feedback system is adopted, and the tension in the winding process is stable and the yield is high

The winding process automatically records all kinds of data, including tension, speed, length, turns, layers, etc.

-

Desktop Small Winding Machine

Product advantages

Product advantagesSmall in size and comprehensive in function, it can be placed on the countertop

It can monitor the arrangement of optic fibers on the fiber receiving side in real time

Adopt on-line tension closed-loop feedback system, and the tension in the winding process is stable

Adopt precision servo motion control system and PLC control system, with accurate operation and high degree of automation

Winding process automatically records all kinds of data, including: tension, speed, length, etc.

-

Fiber Rewinding Machine

Product advantages

Product advantagesSingle person operation and simple operation

Adopt precision servo motion control system and PLC control system, with accurate operation and high degree of automation

Adopt on-line tension closed-loop feedback system, and the tension in the winding process is stable

Winding process automatically records all kinds of data, including: tension, speed, length, etc.

-

Compact Fiber Rewinder

Product advantages

Product advantagesSmall in size, it can be placed on the countertop

Adopt on-line tension closed-loop feedback system, and the tension in the winding process is stable

Adopt precision servo motion control system and PLC control system, with accurate operation and high degree of automation

Running process automatically records all kinds of data, including: tension, speed, length, etc.

-

Fiber Defect Detector Type I

Product advantages

Product advantagesIt is used to detect the number and position of defects such as depressions and bulges on the surface of optic fibers

Single person operation and simple operation

Special structural design can reduce additional torsion

Adopt precision servo motion control system and PLC control system, with accurate operation and high degree of automation

Adopt on-line tension closed-loop feedback system, and the tension in the winding process is stable

The running process automatically records all kinds of data, including tension, speed, length, fiber diameter, number of bump defects, etc.

-

Fiber Defect Detector Type II

Product advantages

Product advantagesIt is used to detect the number and position of defects such as depressions and bulges on the surface of optic fibers

Single person operation and simple operation

Special structural design can reduce additional torsion

Adopt precision servo motion control system and PLC control system, with accurate operation and high degree of automation

Adopt on-line tension closed-loop feedback system, and the tension in the running process is stable

The running process automatically records all kinds of data, including tension, speed, length, fiber diameter, number of bump defects, etc.

-

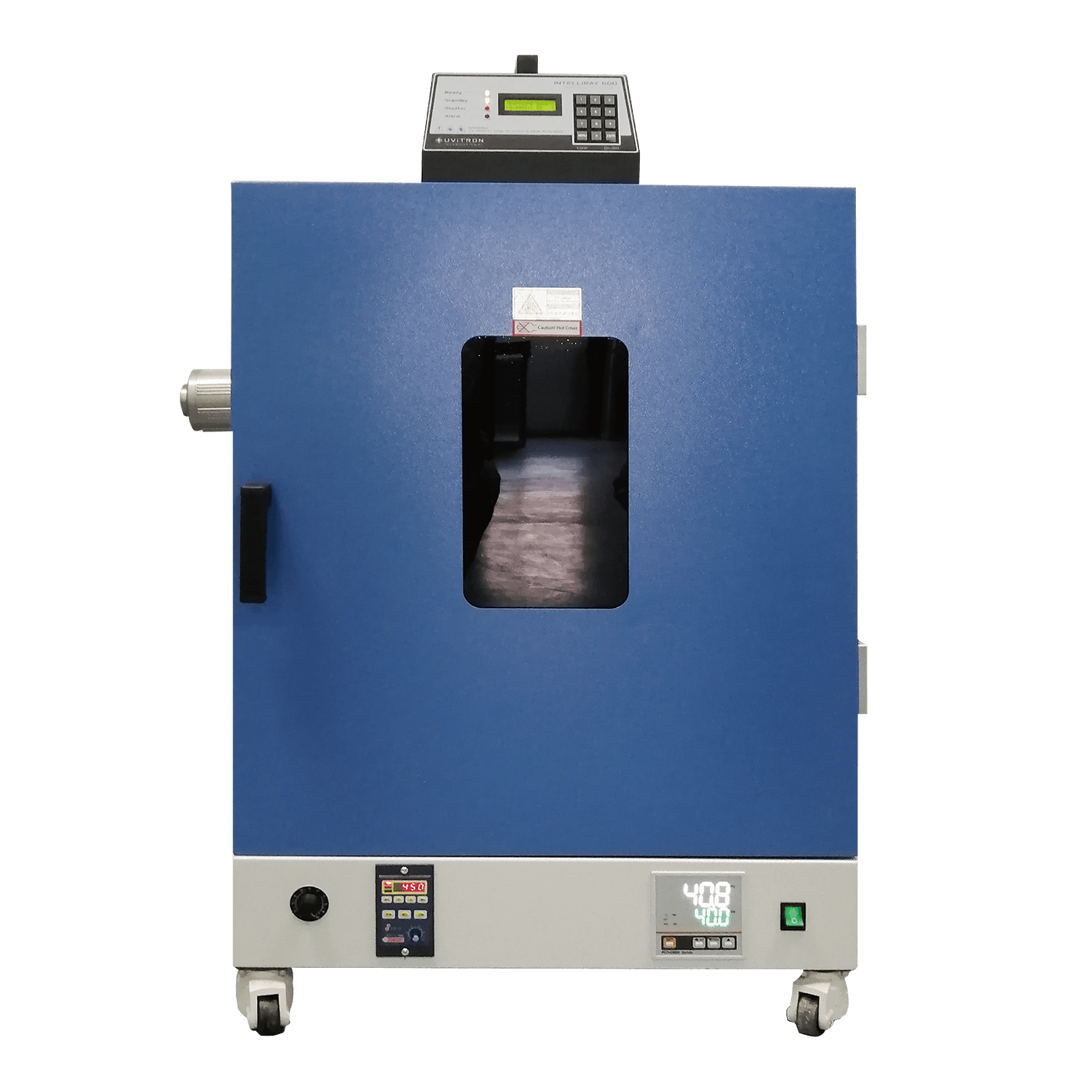

UV Curing Furnace

Product advantages

Product advantagesAccurate temperature control

Suitable for curing various optic fiber coils

Convenient and practical, with complete curing functions and high curing efficiency

-

-

Hotline

- 0086-027-87981568

-

-

-

Email

- sales@yoec.com.cn

-

-

-

Contact

Us

-

-

-