-

Fiber Drawing Tower

Product advantages

Product advantagesThe software is independently developed, with strong scalability, remote automatic control and intuitive and simple operation

Adopt high precision/high stability servo motor system for mechanical motion control

High-resolution caliper and tension measuring instrument are used to accurately control the outer diameter and tension of optic fiber

High-quality precision pneumatic components and mass flow controller can accurately control gas pressure and flow

Adopt high-precision flow control valve, which can accurately control waterway flow

The upper computer adopts industrial control computer, and the lower computer adopts PLC programmable controller, which can automatically draw equal diameter optic fiber

-

Preform Production Equipment

Product advantages

Product advantagesMCVD technology can be used to produce a variety of products: Communication fiber (SM, DSF, NZ-DSF, GI multimode, step index single mode fiber, etc.); Sensor fiber and amplifier fiber with different components and materials; Other special optic fibers with wide applications

MCVD rod making system has precise parametric process setting

The modular structure design adopted by MCVD rod making system can adapt to the manufacturing requirements of various silicon-based fiber preforms

MCVD rod making system has simple equipment, low investment cost and wide application range

MCVD rod making system can provide precise heating bubbling chamber and process line for preform production

All gases in MCVD rod making system are controlled by local particle filtration (0.003 micron) and pressure regulation, and dual-mass flow controller is adopted according to the latest MFCs digital technical standard to improve the control accuracy of its process line

MCVD lathe provides thermal protection cover: to ensure thermal radiation, eliminate hot air, safety in case of large leakage and mechanical failure, ensure the cleanliness of the workshop and protect the health of workers

The MCVD rod making system uses humanized man-machine operation interface, which is simple and friendly to operate and can be customized according to customer requirements

MCVD bar making system can provide lathes of different lengths: 2100 to 3000mm

MCVD lathes can provide a variety of quartz and stainless steel burners of different sizes and models

-

Automatic Fiber Double Drum Winder

Product advantages

Product advantagesThe double wire reel machine automatically changes the disc online, and there is no need to slow down and stop the machine in the production process

The equipment adopts steel base with good rigidity and stability

Closed-loop control of wire winding tension, and the tension can be adjusted online

The equipment has compact structure and elegant appearance

Precision servo motion control system ensures fiber arrangement accuracy

Rich functions and easy operation

Monitor all kinds of data, such as tension, speed, length (kilometers), etc.

-

Optic Fiber Proof-tester

Product advantages

Product advantagesIt has the functions of optic fiber diameter detection, defect detection, online static electricity removal, purging and so on

Single person operation and simple operatio

Adopt precision servo motion control system and PLC control system, with accurate operation and high degree of automation

The online tension closed- loop feedback system is adopted, and the tension in the screening process is stable

Record various data during the screening process, including screening real- time speed, screening real-time tension, length and fiber diameter

-

Large Core Optic Fiber Proof-tester

Product advantages

Product advantagesWith on-line static electricity removal functio

Optic fiber diameter detection, defect detection, purging and other functions are optional

It has the function of retracting and retracting double rows of fibers to reduce torsion introduction

Adopt precision servo motion control system and PLC control system, with accurate operation and high degree of automation

The online tension closed- loop feedback system is adopted, and the tension in the screening process is stable

Record various data during the screening process, including screening real- time speed, screening real-time tension, length and fiber diameter

-

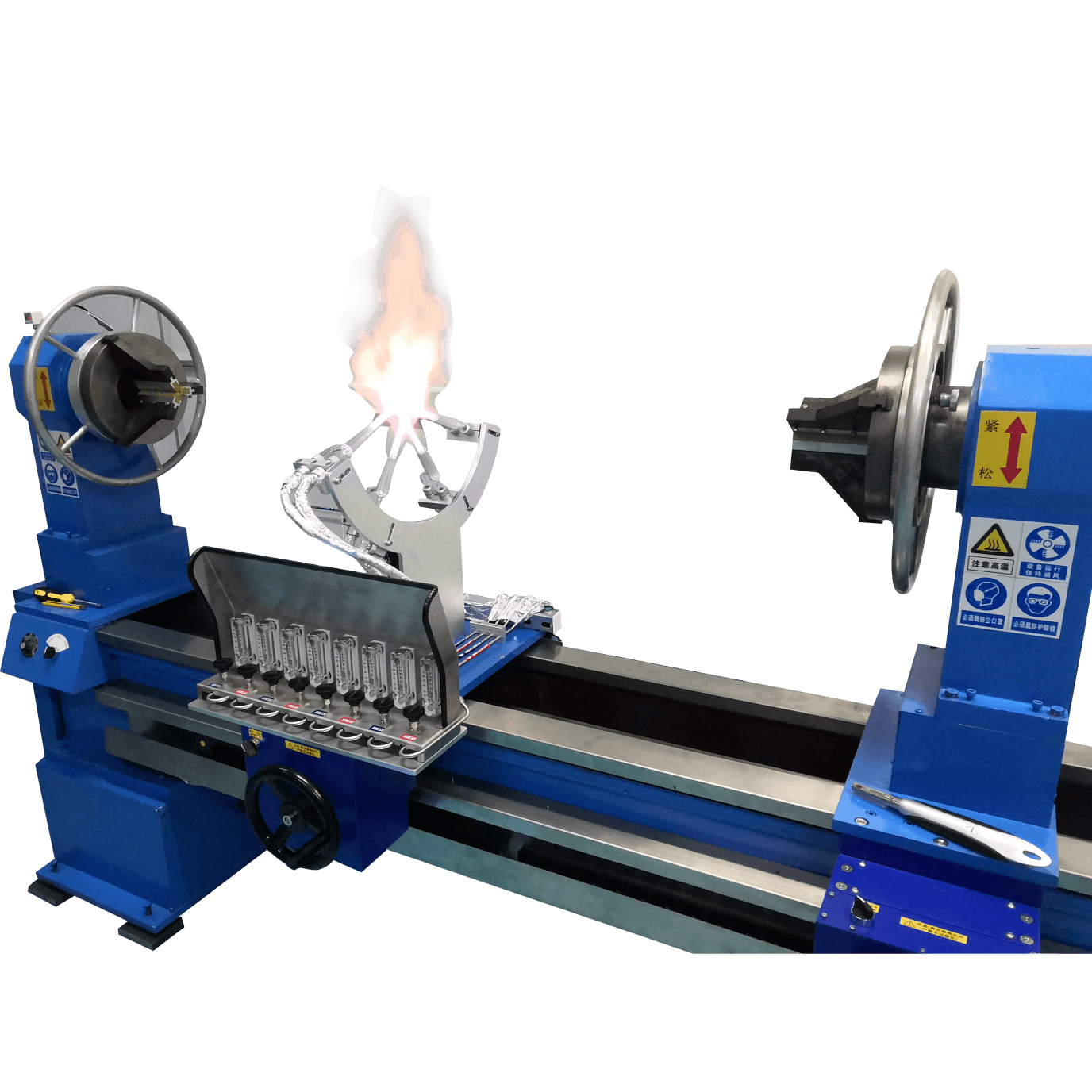

Collapse Lathe Type I

Product advantages

Product advantagesCast iron bed

High precision linear guide rail

The spindle stepless speed regulation

Special glass blowtorch with hydrogen and oxygen flam

Standard vacuum pump and tube-line (optional special gas system)

Flexible switching of manual/automatic functions

The firepower and focal length of blowtorch can be adjusted

Turning claw for easy replacement and daily calibration

-

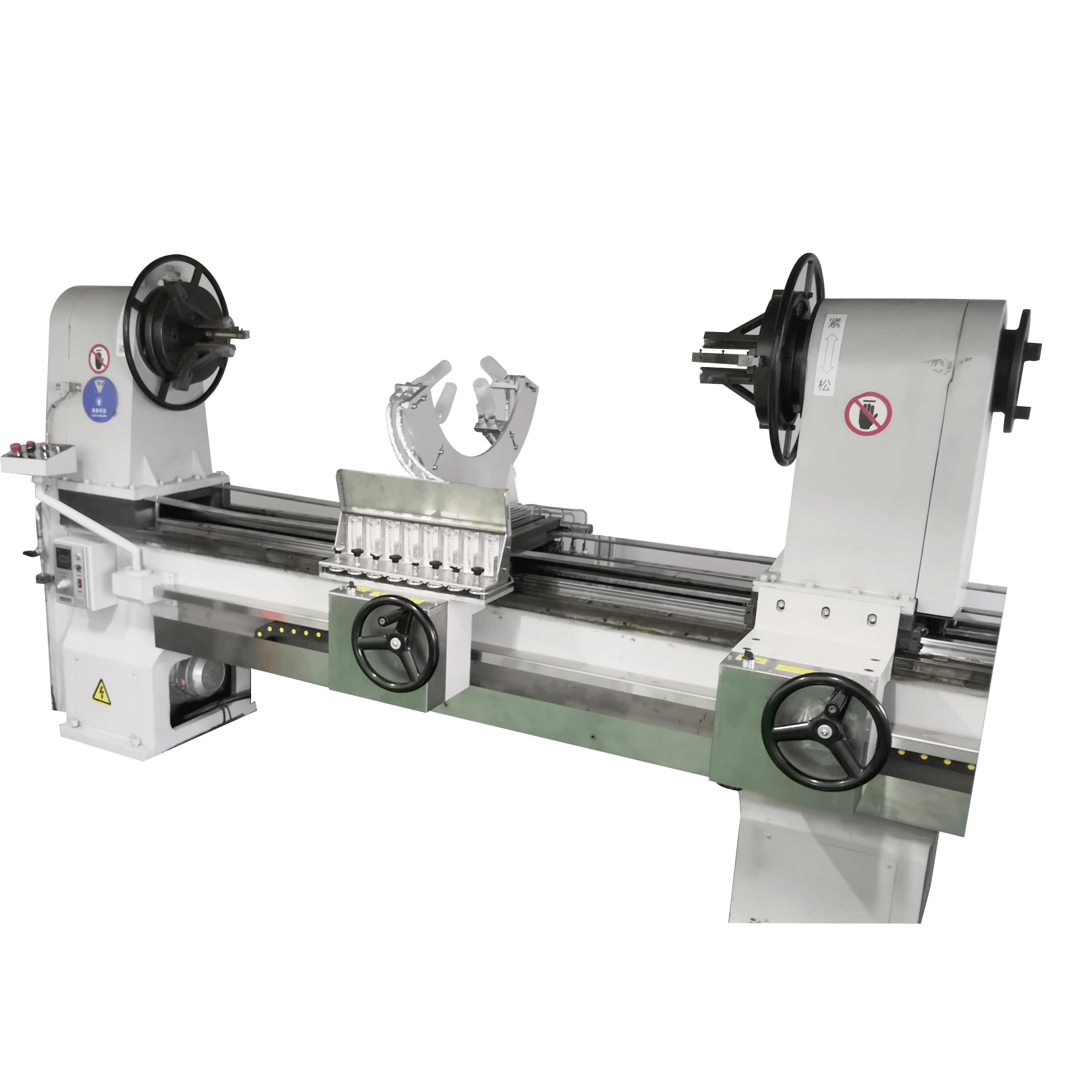

Collapse Lathe Type II

Product advantages

Product advantagesCast iron bed

High precision linear guide rail

The spindle stepless speed regulation

Special glass blowtorch with hydrogen and oxygen flame

Standard vacuum pump and tube-line (optional special gas system)

Flexible switching of manual/automatic functions

The firepower and focal length of blowtorch can be adjusted

Turning claw for easy replacement and daily calibration

-

Numerical Control Quartz Tube and Rod Shaping Grinder

Product advantages

Product advantagesFour-axis numerical control system, fully automatic processing, easy to operate

CNC cast iron bed, mature structure, stable and reliable

High-precision lead screw, with heavy-duty guide rail, forced lubrication to ensure the accuracy of the machine life

BT40 spindle with high speed, high precision and high rigidity, stable operation and anti-knife vibration

Lubrication system, water cooling system and semi-enclosed structure are standard

-

-

Hotline

- 0086-027-87981568

-

-

-

Email

- sales@yoec.com.cn

-

-

-

Contact

Us

-

-

-